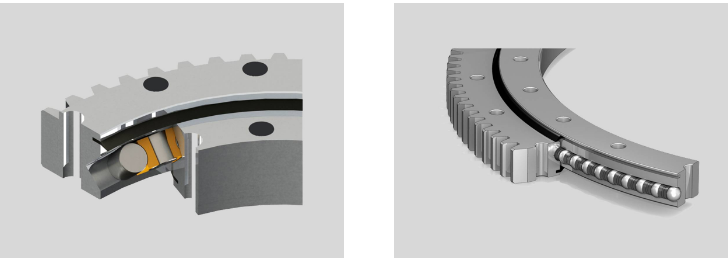

Slewing bearings, often referred to as slew ring, play a crucial role in various heavy-duty applications, including cranes, excavators, wind turbines, and more. Ensuring the reliability and functionality of these components is of utmost importance to prevent costly downtime and accidents. In this article, we will delve into the methods and procedures involved in testing a slewing bearing to guarantee its performance.

- Visual Inspection

The initial step in testing a slewing bearing involves a thorough visual inspection. Examine the external surface for any visible signs of damage, such as cracks, dents, or corrosion. Additionally, check for proper lubrication and ensure that the seals are intact to prevent contaminants from entering the bearing. Visual inspections are essential for identifying any obvious issues that may require further investigation.

- Dimensional Measurements

Accurate measurements are crucial when assessing the condition of a slewing bearing. Measure the inner and outer diameters, as well as the width of the bearing, using precision instruments. Any deviations from the specified dimensions can indicate wear or damage. Comparing these measurements to the manufacturer’s specifications is essential for determining the bearing’s condition.

- Load Testing

Load testing is a fundamental method for evaluating the load-carrying capacity and performance of a slew bearing. This test involves subjecting the bearing to various loads and observing its response. The bearing should be able to withstand the expected operational loads without excessive deflection or deformation. Manufacturers often provide load rating charts to help determine the bearing’s capacity for different load conditions.

- Friction and Torque Testing

Assessing the friction and torque characteristics of a slewing bearing is vital to ensure its efficiency. A torque test involves rotating the bearing while measuring the resistance it encounters. Any significant increase in torque can indicate issues with the internal components, such as damaged raceways or rolling elements. Proper lubrication is essential for minimizing friction and ensuring smooth operation.

- Vibration Analysis

Vibration analysis is a non-destructive testing method used to detect irregularities within a slewing bearing. By measuring the vibration levels during operation, you can identify issues such as misalignment, imbalance, or the presence of foreign particles. Analyzing the vibration data can help pinpoint the root cause of any problems and facilitate timely maintenance or repairs.

- Ultrasonic Testing

Ultrasonic testing is a reliable method for detecting internal defects within a slewing bearing. This technique involves the use of high-frequency sound waves to penetrate the bearing’s structure. Any anomalies, such as cracks or voids, will reflect these waves differently, allowing for their detection. Ultrasonic testing is particularly useful for large and complex slewing bearings.

- Magnetic Particle Testing

Magnetic particle testing is another method for identifying surface and subsurface defects in slewing bearings. It involves applying a magnetic field to the bearing and then applying magnetic particles to the surface. Any discontinuities in the material will cause the particles to gather, making defects visible under proper lighting conditions.

- Radiographic Inspection

Radiographic inspection, also known as X-ray testing, is employed to examine the internal structure of a slewing bearing. This method is effective for detecting hidden defects, such as cracks or inclusions, by capturing images using X-ray radiation. It is particularly valuable for large and thick-section bearings.

In conclusion, testing a slewing bearing is a multifaceted process that encompasses various techniques, including visual inspection, dimensional measurements, load testing, friction and torque analysis, vibration analysis, ultrasonic testing, magnetic particle testing, and radiographic inspection. Regular and thorough testing is essential to ensure the reliability and safety of slewing bearings in critical applications. For more information on slewing bearings and related components, please visit this link.